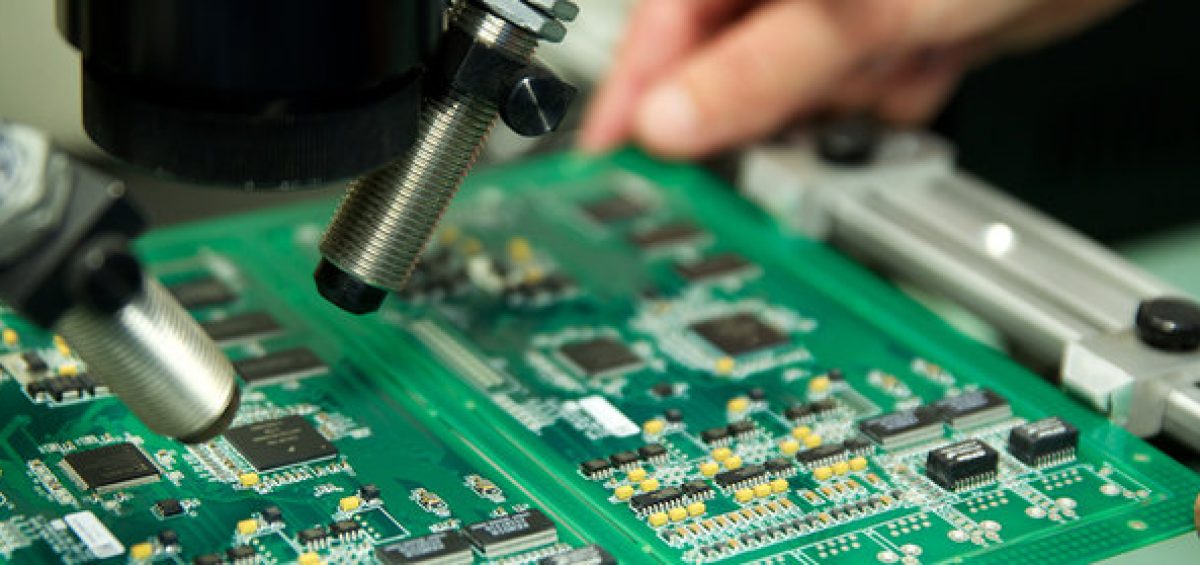

When you have pulled together the perfect PCB design, you will need to find a PCB manufacturing company to make it. One of the most common questions which they will ask you is which material you prefer the PCB to be constructed in. What should you choose? Let’s take a look at some of the options.

FR-4

This material is a flame-retardant fibreglass with a resin binder. It has been around since 1968 and has been used in many different projects over the years but crucially in PCB manufacture. FR-4 is one of the most common materials you will find for PCBs. Together with the copper cladding to show where the components are, it makes the iconic circuit board design of green and copper which we all know and loves. If you are looking for a board made from FR-4, it may also be referred to as copper-clad laminate.

Rigid-Flex

If you are looking for something with a little more give, you should consider looking for a company which manufactures rigid-flex circuit boards. As you might expect from the name, these are circuit boards which can be bent and rotated in any direction without harming the components. It can even be wrapped around the larger mount with no detriment to the function of the circuit board itself.

If you need something which can be used in all sorts of scenarios, rigid-flex might be an option for you. You can even further customise its functionality by choosing the grade of Kapton used in its production. There are fire-retardant options, like FR-4, and there are also some adhesive-less boards designed for high-performance circuitry.

Aluminium

Instead of choosing a board made from a resin or fibreglass, you could also opt for one made with an aluminium base. These are constructed from the aluminium, a thermally conductive insulating dielectric and then the copper laminate. These types of PCBs are only suitable for single-sided PCBs as the metal side is not an insulated. It is most often used for surface-mounted devices such as ignition systems, aircraft landing lights, or street lighting.

Aluminium PCBs are heftier than others and they also tend to be a little cheaper. If you are looking for a PCB that needs a bit of weight behind it, you might want to consider making it out of aluminium.

Which to Choose?

When you are trying to work out which PCB material would be best for you to use, it is important that you think about the final use of the PCB. This will quite often dictate what the material it is manufactured from needs to be. Something which needs to bend well will need to be made from rigid-flex while a test piece might do exceptionally well when made from FR-4. When it comes to PCB design, you should always keep your eye on the final design. Design the PCB you want from the beginning and this will always help to inform which of the materials you should use for manufacture.